Operating Room Ceiling Surgical Light Installation Construction Method

Surgical light is an indispensable lighting facility for the surgery in hospitals. In order to make the ceiling surgical light can be aligned with the irradiated parts, often with greater force to push up, pull down, twist and other operations, the stress relationship of the lamp is complicated. Therefore, the quality of its installation directly affects the safe use and function of the equipment. According to the different building structure of operating room, sufficient attention should be paid to how to install the operating room light with high quality, so that it can be used for a long time without structural malfunction.

There are two main types of structures currently used as operating room roof surfaces: One type of roof is cast-in-place concrete, installation components of operating room light has been buried in the specified position, and passed safety calculations(In other words, the installation of surgical light was pre-designed in the construction drawings). In this case, after reviewing the drawings and understanding the construction situation on site, If there is no doubt, the installation of the ceiling surgical lamp can be carried out directly.

Another type of roof, structures are other forms, such as the roof surface is cast-in-place reinforced concrete, but not pre-embedded installation components, or the roof is a prefabricated cement hollow cover and other construction type, not suitable for direct installation of surgical lights, which is relatively common in small and medium-sized hospitals, this article introduces the construction method in this case, for your reference.

First of all, the construction workers need to determine a reasonable and reliable installation plan according to the civil structure and the width and height dimensions of the operating room, before installing the ceiling surgical light.

It is understood that most hospitals around the world used their own technology and resources to install lamps in a variety of forms, with varying levels and quality of installation. Such as punching holes in the roof plate, using expansion bolts to fix the shadowless lamp mounting components, this method does not apply to prefabricated hollow slabs or other simple roofs, even if the roof is cast-in-place reinforced concrete structure, Since the fixing bolt is in line with the sagging gravity of the shadowless lamp, Bolts may come loose and fall off during long-term use and are not reliable. For cast-in-place reinforced concrete roofs, another method is to peel off local cement to reveal the mesh reinforcement and then weld the shadowless light member onto the steel. Disadvantages of this method: First, it affects the strength and aesthetics of the roof surface. Secondly, reliability has a great relationship with the quality of construction. It is difficult to find the main steel bar under concrete floor, and installer work on his back, the construction quality is difficult to guarantee, etc.

This article recommends a more reasonable construction method, which uses the concrete ring beam on both sides of the roof surface (or the load-bearing wall on both sides) to erect horizontal beams, then install the surgical light under the horizontal beam. This method has the advantages of high reliability, convenient installation, no damage to the original roof surface, wide range of use, see installation diagram.

Horizontal beam in the diagram can use 10# channel steel, according to the force effect, the groove should be in the horizontal direction, as a simple support beam structure fixed at both ends, the strength of the channel itself is not a problem by the weight of the load. When installing, the key is to select and fix beam strutting piece at both ends, which bear the full weight of the ceiling surgical light and the horizontal beam, as well as all the external forces generated during use, 15# angle iron or 15/10# unequal angle iron can be used, fixed to the side of the ring beam with 6 pieces of M20 through-wall bolts or expansion bolts respectively.

As you can see from the chart, fixed bolts are largely unaffected by tension and will not be pulled out, and the shear force that can be withstood far exceeds the requirements of the load. Horizontal beams can be bolted to two supporting planes to prevent horizontal movement. Horizontal beams should be made of channel steel produced by formal manufacturers, without distortion and of good quality. It should not be too short, about 10mm shorter than the width of the room, don't try to save material and use the method of short-term material extension.

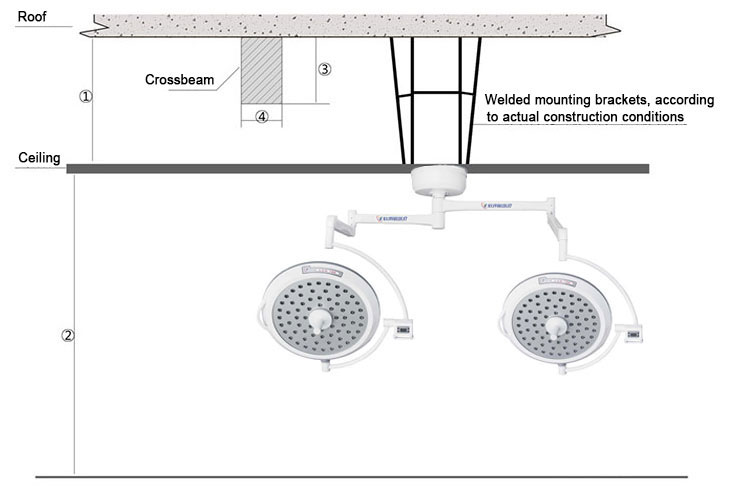

Installation requirements measurement chart (Take YCLED700/500 for example)

It is recommended to be installed on concrete floors or beams. If the ceiling is completed, remove part of the ceiling first and then install the light, then repair the ceiling after installation.

The optimal height for part 2 in the picture is 2.8-3.0 meters

1. If there is no crossbeam

1.1 Part 1 of the picture is the height from ceiling to roof

1.2 Part 2 of the picture is the height from ceiling to ground

2. If there is a crossbeam structure and it is required to be mounted to the crossbeam, the following data need to be measured

2.1 Ceiling to roof height (Part 1)

2.2 Height of the crossbeam (Part 3)

2.3 Width of the crossbeam (Part 4)

In addition, we will discuss the expansion component. In general, the roof of the operating room is high from the ground, and the operating room with central air conditioning is even higher. If the ceiling surgical light is installed directly on the roof surface, it's too high from the ground and cannot be used, so it's necessary to use extension component.

There are several types of extensions: triangular frame shape, rectangle or square frame, etc. Round pipe flange shape is recommended here, compared with other types, it has the advantages of simple structure, high reliability, good force balance, good stability, low cost, easy manufacturing and installation. Seamless steel tubes are available, diameter is not less than 150mm, wall thickness is more than 8mm, length can be cut as needed. Round pipe flanges can be cut from iron plates not less than 8mm thick, and the diameter can be determined according to the distance between the two horizontal beams and the size of the operating lamp flange. When welding into one piece, attention should be paid to the quality and parallelism of the two flanges. The flange and tube body should be connected by steel reinforcement.

For the double domes surgical light, especially surgical light with counterweight, longer bolts should be used first to connect the extension component to the operating lamp, so that it's easy to string in several nuts to adjust the surgical lamp, to achieve the requirements of balance. Surgical lights should be installed in advance in operating rooms where false ceilings are required, ceiling height and process shall be in cooperation with the constructors, to ensure the matching and beauty of the ceiling and operating room light, and require the ceiling to leave maintenance access. Every step of the installation of operating room light must be carefully inspected and operated, acceptance shall be carried out after construction to ensure the quality of the installation of the ceiling surgical light.

- Previous post:LED Surgical Lamp Common Failures and Solutions

- Next post :Ideal Shadowless Operating Lamp Features